Note: This article is based on chapter 3 of my white paper titled 7 Key CBTC Functions Transit Operators Must Understand. Downloaded it here.

Part 1 of this blog post discussed how to track and protect maintenance vehicles that are not equipped with CBTC equipment. Part 2 will discuss some of the issues involved with equipping maintenance vehicles.

Equipping maintenance vehicles with a VC (Vehicle Controller) offers consistency across the operating environment; CBTC rules apply to passenger trains as well as maintenance vehicles. But equipping maintenance vehicles is not the same as equipping passenger trains because maintenance vehicles have their own unique set of problems.

Each passenger train is identical to the next such as the number of cars, type of cars, propulsion characteristics, braking characteristics and physical characteristics. Therefore, the VC hardware and software are generic and the entire passenger fleet has the same equipment and firmware.

This does not apply to maintenance vehicles because a fleet of 60 maintenance vehicles can have up to 30 different types of maintenance vehicles. To complicate matters further, they can all interchange to create a different consist (a consist is a series of individual cars coupled together) depending on the maintenance activity planned for that day. The VC must take into consideration all possible maintenance vehicle combinations to determine the train consist and each consist will have different characteristics such as size, type, braking and propulsion characteristics.

The Operator must incorporate these variables to create a design that allows the maintenance vehicles to operate under the same rules as passenger trains. This must be the objective for any design or concept.

Concept

The VC resides on the locomotive (powered maintenance vehicle) only. When the locomotive is not coupled to another maintenance vehicle, the position envelope (front and rear position of the train) will match the length of the locomotive (Figure 1).

Figure 1 - Single locomotive (powered maintenance vehicle)

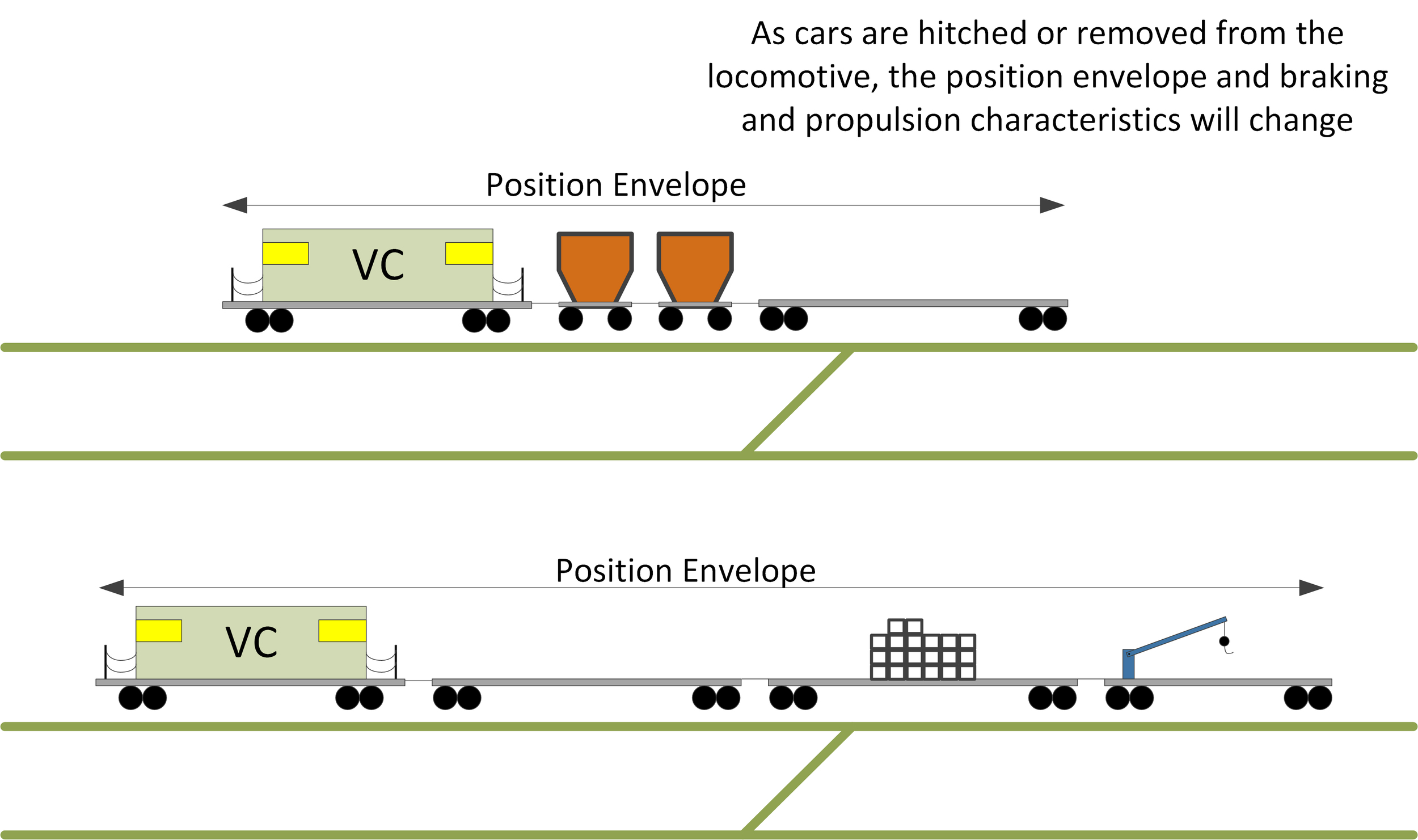

The VC will extend the position envelope if the locomotive is coupled to other types of maintenance vehicles (Figure 2) and this is accomplished if each coupled maintenance vehicle sends its car type ID via the train lines.

The VC database will contain the vehicle characteristics (length, braking and propulsion) of all maintenance vehicles to dynamically calculate the new position envelope and braking & propulsion characteristics. The VC must take into account that some cars will carry cargo; braking and propulsion characteristics must be based on the maximum loading of those cars.

Figure 2 - Locomotive coupled to other cars

A VC able to determine the number of cars and car types it’s coupled to, will operate like a passenger train. Equipped locomotives will enter the mainline at any time and reach their destination without disrupting Service.

This is the standard for which all Operators must strive.

Other Issues

The Supplier is responsible for implementing the concept but the Operator is responsible for delivering maintenance vehicles that are “CBTC ready.” For most Operators, this is the difficult part of the equation.

The concept relies on the coupled maintenance vehicle sending the maintenance vehicle type ID to the VC but this assumes that the maintenance vehicle is “CBTC ready” defined as:

- Space to install CBTC equipment (VC)

- Train lines and/or Ethernet/MVB line available to transmit information to the VC

Operators with an older fleet will probably have no space to install VCs and/or no train lines to send information; some maintenance vehicles are modified passenger cars which add to the complication.

With such an assortment of vehicles, the Operator must assess whether part of the fleet should be decommissioned and replaced with modern maintenance vehicles or retrofitted and upgraded to support CBTC operations before the decision to equip maintenance vehicles is made.

Conclusion

Equipping maintenance vehicles has major implications on the final CBTC solution and how the Operator will use their maintenance vehicles.

Equipping maintenance vehicles permits a consistent operating environment where CBTC rules apply to passenger trains and maintenance vehicles. But it may mean retrofitting a portion of the fleet and replacing a portion to support CBTC operations. Depending on the age and size of the fleet, capital costs could be large.

Not equipping maintenance vehicles creates two operational environments; one for passenger trains operating under CBTC rules and another for maintenance vehicles operating under conventional or TPR rules. Further, the capital and running maintenance costs (over the life of the system) are large if the decision to implement a fallback mode of operation is taken; TPR is a simple low cost solution if the operating environment is conducive to it.

Both options can be costly and the Operator must take careful stock of their operating environment and the state of their assets (maintenance vehicles) before deciding on equipping or not equipping maintenance vehicle. The Operator must strive to create a consistent operational environment where all trains operate under the same rules.